The Waste Water Treatment Machine Hollow Paddle Dryer/Vacuum Dryer//Spray Dryer/Drying Machine, Belt Dryer, Spin Flash Dryer

Basic Info

| Model NO. | JYG |

| After-sales Service | Online Technical Supporting |

| Warranty | 1 Year |

| Type | Vacuum Drying Equipment |

| Application | Block |

| Fuel | Heavy Oil |

| Operating Pressure | Vacuum |

| Roller Number | Steam |

| Cloth Membrane Forms | Top Feed |

| Vacuum Drying Equipment Type | Vacuum Harrow |

| Condition | New |

| Drying Method | Heating |

| Hot Air Contact Method | Heat Conduction |

| Heat Source and Heating Method | Steam or Thermal Oil Heating |

| The Dryer′s Capacity Range | From 40 to 150 Tons Per Day |

| Drying Process | Continuous Automatic Drying |

| Heat Exchange Area | 6 M2 - 200m2 |

| Processing Capacity | 125-450kg/H ( 80%~40% ) |

| Heating Method | Indirect Heating |

| Installation | Engineer Oversea Installation |

| Transport Package | Seaworth |

| Specification | 5-5000kg |

| Trademark | ZHENGAN |

| Origin | Changzhou |

| HS Code | 8419399090 |

| Production Capacity | 4 Sets/Month |

Product Description

Hi, I am Joanna

And now working for Jiangsu zhenxing drying equipment co.,ltdI know you are looking for good-quality dryer equipment.

Any questions about the drying machine feel free to contact me, I would like to offer you full technical support and online video service, it will help you to know about the full drying system very well.

So our company can be a good choice, WHY?

Product Description

Introduction

Thermal drying is an intermediate sludge treatment process that consists of evaporating the water in the sludge. It significantly reduces the volume and weight of the sludge so that it is easier to recover.The hollow paddle dryer is an indirect heating type composed of the casing with a jacket and shaft with a disc that contains steam or other heating media, Hollow paddle dryer (also called disc dryer) can dry all kinds of animal waste in an atmosphere controlled environment with multipoint thermal control, such as poultry entrails, municipal sludge, textile sludge, catering sludge, chemical sludge, etc.The paddle (discs ) cover 80% of the total heating surface.Compared to the other indirect heating dryer, the disc has a compact design and high thermal efficiency.1. JYG sludge dryer has low energy consumption: due to indirect heating, it does not carry a large amount of air to take away the heat, and the outer wall of the dryer is provided with a thermal insulation layer.2. JYG sludge dryer has low use cost: it has a huge heat transfer surface per unit effective volume, which shortens the treatment time, reduces the size of the equipment, and greatly reduces the building area and building space.3. Wide range of materials to be treated: different thermal media are used to treat both heat-sensitive materials and materials requiring high-temperature treatment. Common media include steam, heat transfer oil, hot water, cooling water, etc., which can be operated continuously or intermittently. It can be used in many fields.4. Small environmental pollution: vacuum or small air volume is used to take away the moisture in the material. The entrainment of dust and material is very small, and the evaporation of the material solvent is very small, which is convenient for treatment. Closed-circuit circulation can be adopted for contaminated materials or working conditions requiring solvent recovery.5. Low operation cost: low-speed mixing and reasonable structure, small wear, and low maintenance cost.6. Stable operation: due to the special compression expansion mixing function of the wedge-shaped blade, the material particles are in full contact with the heat transfer surface. In the axial range, the temperature, humidity, and mixing gradient of the material are very small, so as to ensure the stability of the process.

Performance:

1. The paddle dryer has low energy consumption: due to indirect heating, it does not carry a large amount of air and takes away heat. The outer wall of the dryer is provided with an insulating layer. For slurry materials, it only needs a small amount of heat to evaporate 1kg of water.

2. The cost of the paddle dryer system is low: there is a huge heat transfer surface in the unit effective volume, which shortens the processing time. Due to the smaller size of the equipment, the building area and building space are reduced.

3. Wide range of materials to be treated: different thermal media can be used to treat both heat-sensitive materials and materials requiring high-temperature treatment. Common media include steam, heat transfer oil, hot water, cooling water, etc. It can be operated continuously or intermittently and can be used in many fields.

4. Little environmental pollution: no use of portable air and little entrainment of powder materials. The evaporation capacity of material solvent is very small, which is convenient for treatment. Closed-circuit circulation can be adopted for contaminated materials or working conditions requiring solvent recovery.

5. Low operating cost: the equipment operates normally, only 1 hour/day · person. Low-speed mixing and reasonable structure. The wear is small and the maintenance cost is very low.

6. Due to the small temperature gradient in the mixing section, the axial expansion of the material and the humidity of the mixing blade ensure the stability of the material.

You may be interested in the following information:

- Detail of equipment, and instruments. Brands.

- Detail of the construction material.

- Detail of automation

- Whether or not it includes assembly.

- Startup and guarantees.

- Process parameters.

- Percentage of product loss.

- Quality parameters of the final product.

- Recommended operating time between power line CIP ("Clean In Place").

- Information plans for civil works, indicating necessary dimensions and levels, loads on slabs and bases, etc.

- The layout of the installation.

- Instruction manual for operation and maintenance.

- List of spare parts.

Detailed Photos

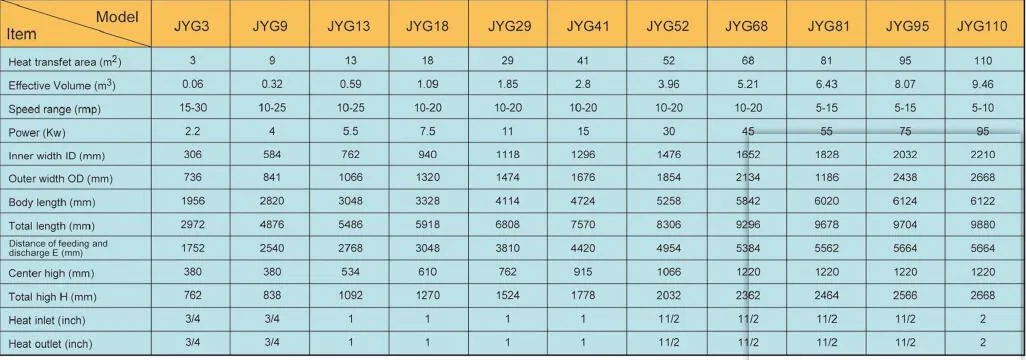

Product Parameters

Material and liquid conditions

| Process method | Solid content | Feed capacity | Output capacity |

| Wastewater: 40 m3/h | |||

| Screw filter | 20% | 4000kg/h | 830kg/h |

| Hollow Paddle Dryer(steam at 0.5Mpa) | 85% | 830kg/h | 195kg/h |

Process conditions

| Drying method: | heating |

| Hot air contact method: | Heat conduction |

| Heat source and heating method: | steam or thermal oil heating |

| Dust removal method: | Two-stage cyclone |

| Product collection method: | conveyor screw |

| The dryer's capacity range: | from 40 to 150 tons per day |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Heating source: | Steam |

| Installation: | Engineer Oversea Installation |

| Drying process: | Continuous Automatic Drying |

| Heating method: | Indirect Heating |

| Heat exchange area: | 6 m2 - 200m2 |

| Processing capacity: | 125-450kg/h ( 80%~40% ) |

Application

Paddle dryer (vacuum disc dryer) has been successfully used in food, chemical, petrochemical, dye, industrial sludge, and other fields.The characteristics of heat transfer, cooling, and stirring of the equipment enable it to complete the following unit operations: combustion (low temperature), cooling, drying (solvent recovery), heating (melting), reaction, and sterilization.At the same time, the stirring blade is the heat transfer surface, which increases the heat transfer area per unit effective volume and shortens the treatment time. The heat transfer surface of the wedge-shaped blade also has the function of self-cleaning.Compression - expansion mixing function makes the materials mix evenly. The material moves in a "piston flow" along the axial direction. In the axial range, the gradient of temperature, humidity, and mixing degree of the material is very small. Using heat transfer oil or steam as a thermal medium, the paddle dryer can complete low-temperature combustion.For example, the combustion of calcium sulfate dihydrate (Ca2SO4 · 2H2O) is transformed into calcium sulfate hemihydrate (Ca2SO4 · 1 / 22h2o). Sodium bicarbonate (NaHCO3) is converted into soda ash (na2hco3) by calcination. The cooling medium, such as water and cooling brine, can be used for cooling. For example, the paddle-type soda cooler used in the soda ash industry replaces the old air-cooled soda cooler, saving energy and tail gas treatment equipment and reducing operating costs. Drying, the main function of the equipment does not to use hot air, so that solvent recovery, energy consumption, and environmental control are in an ideal state of easy treatment. It is especially suitable for solvent recovery, flammable, and easily oxidized heat-sensitive materials. It has been widely used in fine chemical, petrochemical, and dye industries. In the axial section, the uniformity of temperature, humidity, and mixing degree makes the equipment can be used to heat or melt or react with some solid materials. It has been successfully used in compound fertilizer and modified starch industries. The paddle dryer can be used to sterilize food and flour. The large heating area in the unit effective volume can quickly heat the material to the sterilization temperature, avoiding the change of material quality caused by long-time heating.

After Sales Service

Installation and Commissioning and Training:

1. Buyers arrange installation and debugging by themselves under a manual book from the supplier.2. If the buyer requires engineers from the seller's party, the buyer should arrange the following items:(A)Within 30 days after the machines are delivered to the buyer's factory, the buyer shall inform the seller to arrange engineers to the buyer's factory for installation, commissioning, test, and training machine operators.(B)The buyer should provide the engineers(1-2 person) the boarding and lodging, transportation during the engineer's stay in the buyer's country, and round trip air ticket and visa fee for the engineers. Besides, the buyer should pay the money as salary for one engineer per day.

Product Presentation

Company Profile

ZHENXING was founded in 1993. We are specialized in the development and manufacturing of dryers, mixers, granulators, grinders, and etc. Our company has cooperated with a number of research institutions since 2007 and we have established the largest sludge drying equipment testing center in China. All Dryer is widely applied in all kinds of industrial fields.We are certified with the ISO9001 quality management system. We follow a strict quality control procedure and we provide high-quality products with prompt after-sales services and technical supports.Our drying equipment has been exported to North America, Pakistan, India, Vietnam, Russia, and other countries.I am a trustworthy and reliable industrial dryer specialist, a leading manufacturer of drying fields based in Changzhou China. With more than 10 years of experience in designing and fabricating the dryer machine.I understand that drying technology and quality are the key to meet with the production capacity requirement, and the dryer working performance well is our aim, which is why in DRYING TECHNOLOGY I always put the needs of our clients first.

FAQ

What do I do?

I am focusing on providing the industrial drying system, which includes the spray dryer, flash dryer, drum dryer, vacuum harrow dryer, high-temperature rotary calcining dryer, mesh belt dryer, continuous tray dryer, pigment production line.Our related factory has extensive experience in exporting to the USA, Russia, Malaysia, India, and North America.

Why choose me?

To provide you with the most cost-effective drying solutions.Offer you 24hour online free technical support.Offer you full support on design, fabricate, installation service.The updated production schedule is for you in real-time.