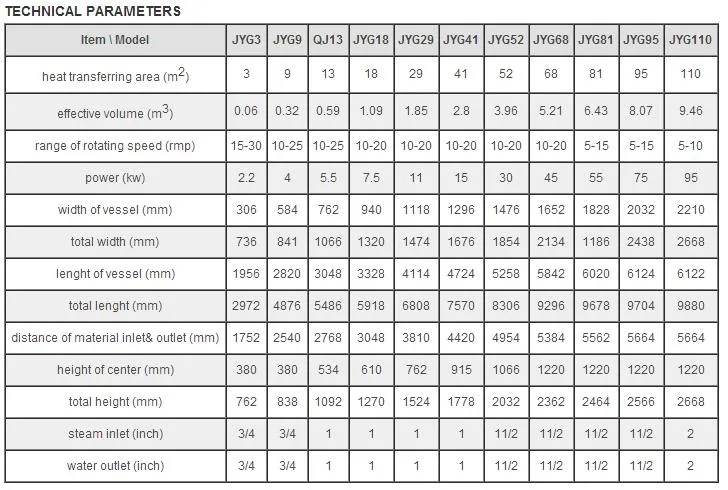

Hollow Blade Sludge Dryer Machine Vacuum Rake Rotary Drum Paddle Dryer with ASME Design Certificate

DESCRIPTION This machine can indirectly heat or cool the materials in paste, granules, powders and slurries. It can also;

Basic Info

| Model NO. | KJG |

| After-sales Service | After Sell Service |

| Warranty | 12 Months |

| Condition | New |

| Certification | GMA, QS, FDA, ISO, CE |

| Automation | Automatic |

| Screw | Twin-Screw |

| Treatment | Chemical Treatment |

| Power | 11kw |

| Heat Transfer Area | 29 Square Meter |

| Width Vessel | 1118mm |

| Height of Center | 762mm |

| Heating Source | Electric or Steam or Oil |

| Transport Package | Wooden Container |

| Trademark | JXX |

| Origin | China |

| HS Code | 8419399090 |

| Production Capacity | 30 Sets/Month |

Product Description

DESCRIPTIONThis machine can indirectly heat or cool the materials in paste, granules, powders and slurries. It can also complete the unit process of drying, cooling, heating, sterilization, reaction and low temperature combustion. the special heat-transfer stirring blade wedge type in the equipment has high heat-transfer efficiency and its heat-transfer surface has self-cleaning function.

WORKING PRINCIPLE

A hollow shaft is densely arranged with hollow wedge-shaped blade; heat medium flow to the hollow blades through hollow shaft. the heat transfer area per unit effective volume is large. Temperature of heat medium is from -40 ºC to 320 ºC, may be in the form of water vapor or liquid, such as hot water or heat transfer oil. Indirect conduction heating has no air to carry away the heat, so the heat is all used to heat the material, and the only heat loss is the heat dissipated around from the heat insulation layer. Heat-transfer surface of wedge-shaped blade has self-cleaning function. Relative movements between particles and the wedge-shaped surfaces produce wash effect, which can wash away the adhered material on the surface of the blade, so that a clean heat transfer surface is maintained in the operation. the shell of blade dryer is Ω-type, generally two to four hollow stirring shafts installed in the shell. the shell is equipped with end cover and top to prevent dust escaping.Heat transfer medium flows through the rotary joint, shell jacket and hollow stirring shaft. Depending on the type of heat medium, hollow stirring shafts have different internal structures to ensure optimal heat transfer effect.

FEATURES

1. Blade dryer is low energy-consumption: due to the indirect heating, there is not a lot of air carrying away the heat; the outer wall of the dryer set the insulation layer. for slurry material, it takes only 1.2kg water vapor to evaporate 1kg water.

2. System of blade dryer is low cost; the heat transfer area is large in unit effective volume, which makes shorter the processing time and the smaller device size, greatly reducing its covering area and building space.

It can handle wide ranges of materials: Using different heat medium, it can not only deal with heat-sensitive materials, but also materials requiring high temperature treatment. Common media are: steam, heat transfer oil, hot water and cooling water.

3. It supports both continuous operation and intermittent operation; it can be applied in many fields.

Environmental friendly: it does not use carry air and carries very little dust material. Material solvent evaporation is little so it is easy to handle. for materials which may cause pollution or requiring solvent recovery, closed circulation can be applied.

4. Low operating costs: little abrasion, low maintenance cost.

Stable operation: due to the special compression - expansion stirring of wedge-shaped blade, material particles have sufficient contact with the heat transfer surface. In the axial zone, materials have low temperature, low humidity and small mixing gradient so as to ensure the stability of the process.

APPLICABLE MATERIALS

Blade dryer has been successfully applied in the fields of food, chemical, petrochemical, dyes, industrial sludge and so on. Its characteristics of heat transfer, cooling and stirring enable its following unit operation: Combustion (low-temperature), cooling, drying (solvent recovery), heating (melting), reaction and sterilization. Stirring blades also act as the heat transfer surface, so that the heat transfer area per unit effective volume is increased and the processing time is shortened. Wedge-shaped blade heat transfer surface has self-cleaning function and compression - expansion mixing function which makes the material mixed evenly. Materials move into "plug flow" axially. In the axial zone, material has low temperature, low humidity and small mixing gradient. If the heat transfer oil is used to do heat medium, the dryer can accomplish low-temperature combustion. for example: calcium sulfate dihydrate (Ca2SO4 · 2H2O) is combusted into calcium sulfate hemihydrate (Ca2SO4 · 1 / 22H2O); Sodium bicarbonate (NaHCO3) is calcined into sodium carbonate (Na2HCO3). If pumped into cooling medium, such as water, salt water, it can be used for cooling. for example, the blade-type soda ash cooler used in sodium carbonate industry replaces the old air-cooling cooler, saving energy and exhaust treatment equipment so that reducing operating costs. Drying-the main function of the device-do not use hot air, making the solvent recycling, energy consumption and environmental control in a tractable ideal state. It is particularly suitable for materials requiring recovering solvents, flammable, easily oxidized and heat-sensitive materials. It has been widely used in chemical, petrochemical and dye industries. In the axial zone, uniformity of temperature, humidity and degree of mixing makes the device can be used to heat or melt, or do some reaction of solid material. It has been successfully used in the industries of fertilizer and modified starch. Blade dryer can be used for sterilization of food and flour. with large heating area in unit effective volume, the materials will soon be heated to the sterilization temperature, avoiding that long heating may change the quality of materials.

Company ShowCompany introduction: Jiangsu Xingxing Drying EquipmentJiangsu Xingxing Drying Equipment has established in 1998 and it covers an area of 15000 square meters, possesses fixed asset of USD 7 million. The products have exported to US, Singapore, India, Ukraine, Russia, Korea and so on. The company have advanced production equipment , excellent technical team and after-sales service.CERTIFICATEPackage:wooden caseService:pre-sale serviceWe Invite customers to visit our company and communicate on technical requirements face to face.sale serviceResponsible for debugging the equipment according to customers' requirements of various technical data. Our engineers will train our customers about equipment features and operation key points to make sure the equipment running in the best condition.after-sale serviceWe provide installation, debugging, maintenance, training and other services; Provide relevant technical data, equipment, software and related GMP certification materials;Set up after-sales service hotline, and arrange personnel to visit customers every year to know more customer needs,like customer operation problems in the process of production equipment.quality promiseOur company promises strictly operate the ISO9001 quality system certification standards and pharmaceutical equipment GMP audit requirements,promise we provide new equipment. Advanced technology,good quality.Equipment operation safe reliable, affordable, easy to maintain.Equipment warranty period is one year,all the parts for the equipment choose well-known brand.During the warranty when equipment have problem in quality like equipment failure and damage,the company for free maintenance or replacement.We look forward to cooperating with partners from all over the world to build win-win cooperation relationship in long term. Welcome for your visiting.Previous ExhibitionFAQ:1.

Q: Please describe your warranty period. A: 15 months after the equipment is arrived at the destination port or 12 months after the installation and commissioning of the equipment, whichever comes first.2.

Q: Do you provide on-site installation and commissioning? A: Yes, we do. If on request, we'll provide the guidance of on-site installation and commissioning. Usually one mechanical engineer and one electrical engineer to assist.3.

Q: How about the cost of on-site installation and commissioning guidance? A: The cost consists of round-trip air tickets, room and board expenses, service cost (labor cost), and site transportation (or directly provided by client), which shall be paid additionally.4.

Q: Are you a factory or a trading company? A: We are a professional manufacturer. We have own factory and pilot plant for customers to do sample testing.

You may also like

Send inquiry

Send now